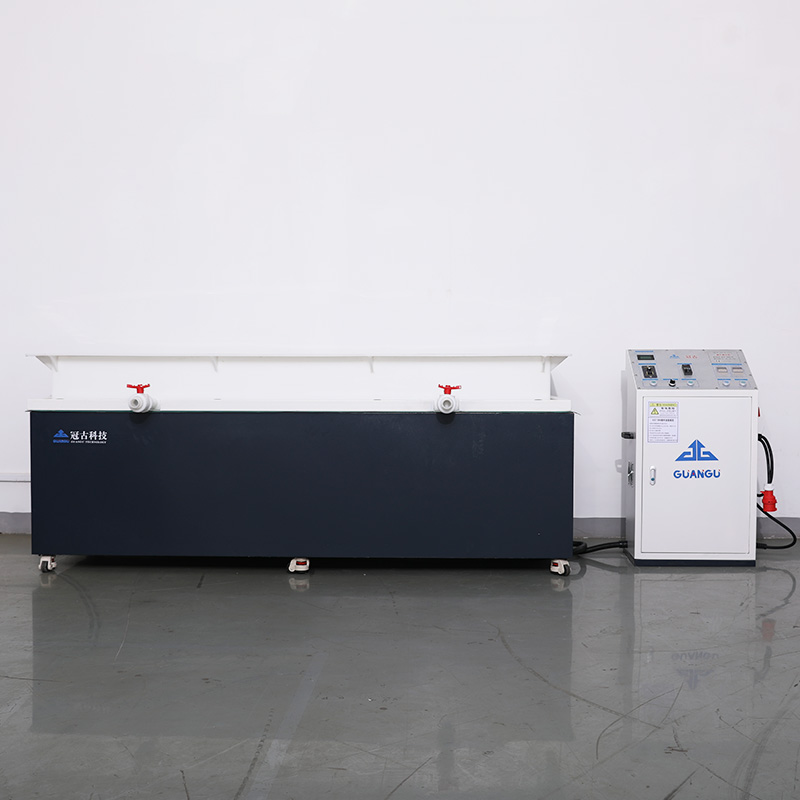

| Product Model | GG2980 |

| Dimensions | 1380*720*1088 |

| Grinding groove size | 1200*520(drum) |

| Power supply | AC380v(50Hz)16A |

| Motor power | 4KW*1 |

| Equipment weight | 410KG |

| Grinding capacity | 25-35Kg |

| Operation mode | Positive and negative rotation |

| Steel needle | 10kg |

| Lapping liquid | 50L |

| Motor speed | 1400 RPM |

| Diameter | 0.2-2.00mm |

Metal surface Philadelphiacleaning machine is a full range of precision hardware workpiece cleaning equipment, can remove workpiece burr without dead Angle, oxide, etc. Metal surface Philadelphiacleaning machine is mainly used for CNC, copper and aluminum parts, Philadelphiaalloy parts, precision hardware workpieces can be seen on the market, metal surface cleaning machine is a new type of equipment introduced by Guanguu, frequency modulation variable speed, save time.